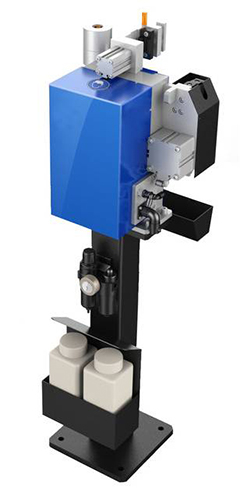

Arc Welding Torch Cleaning Unit

Arc Welding Torch Cleaning Unit is a true plug-and-play solution for robotic welding torch maintenance. Featuring a single-point connector system, the TCS-FP comes equipped with catch tray covers on the reamer blade and wire cutting station for a cleaner, more efficient reaming cycle.

The anti-spatter injection unit for the TCS-FP is a new pneumatic-based application that eliminates the need for a solenoid and allows for activation via the robot's motion.

The protective covering around the injector improves coverage to the welding nozzle and collects more overspray.

TCS-FP Features and Benefits:

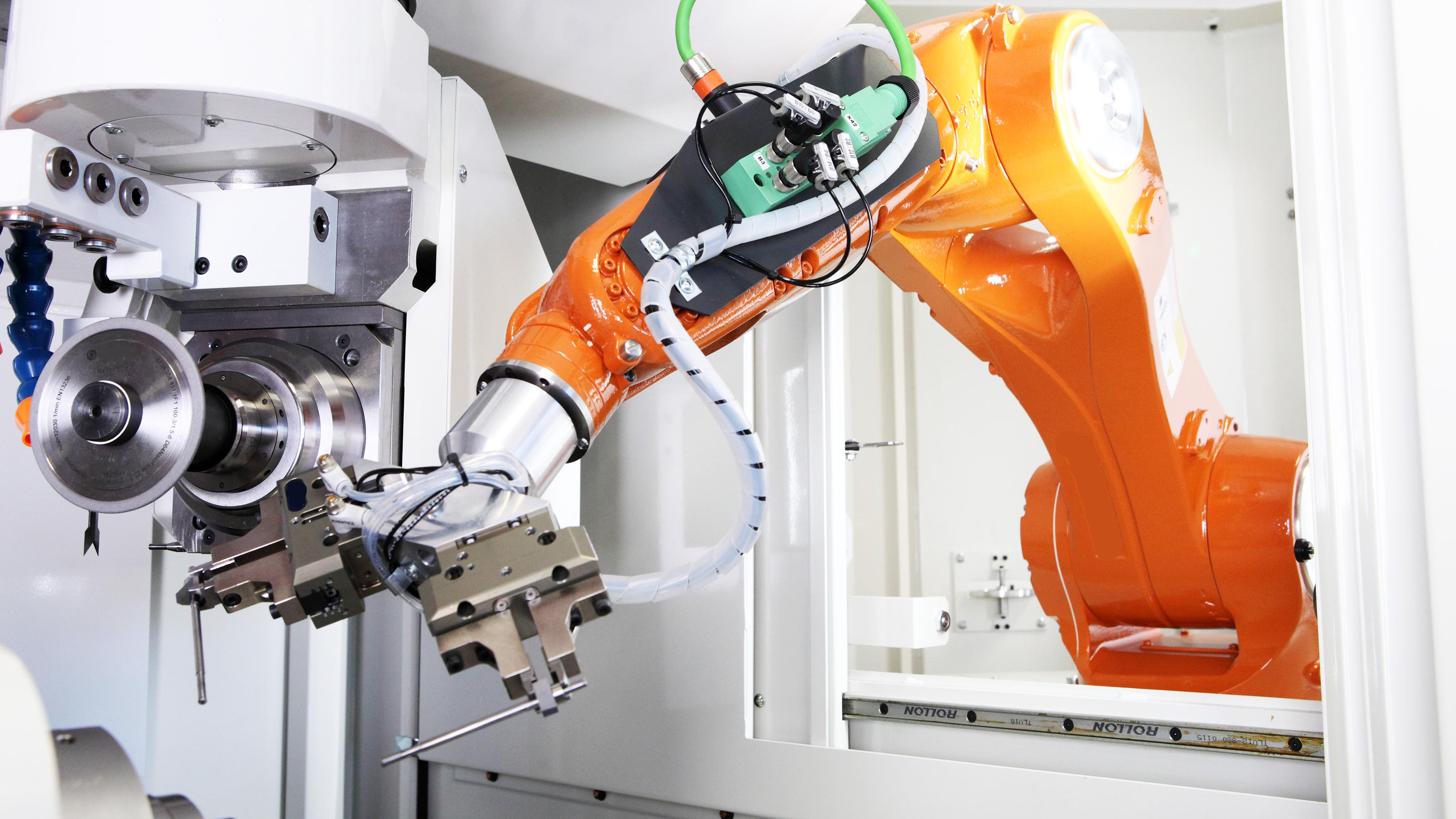

Spot Welding Electrode Tip Dresser RSGSS

The function of the electrodes is to conduct the current and to withstand the high pressures in order to maintain a uniform contact area and to ensure the continued proper relationship between selected current and pressure. Uniform contacting areas should therefore be maintained. Good weld quality is essential and depends, to a considerable degree, upon uniformity of the electrode contact surface. This surface tends to be deformed (mushroomed) with each weld. Primary causes for mushrooming are too soft electrode material, too high welding pressure, too small electrode contact surface, and most importantly, too high welding current. These conditions cause excessive heat build-up and softening of electrode tips. Welding of today´s coated materials also tends to contaminate the face of the electrodes.

As the electrode deforms, the weld control is called upon to "step" up the welding current in order to compensate for "mushroomed" weld tips. Eventually, the production line will have to be shut down in order to replace the electrodes or to manually go in and hand dress the electrodes. This process will improve the weld cycle but in either case, the line is stopped and time is lost. Furthermore the deformed electrodes have caused unnecessary high consumption of energy and electrodes.

In automatic tip dressing, a tip dresser is mounted on the line where it can be accessed by the welding robot. The robot is programmed to dress the electrodes at regular time intervals. The dressing can be done after each working cycle, after every second cycle, and so on. It depends upon how many spot-welds are done in each cycle. For welding in galvanized sheet, dressing after about 25 spot-welds is recommended. The dressing takes approximately 1 to 2 seconds, and is perfomed when the work pieces are loaded, unloaded and transported. Maintaining proper electrode geometry minimizes production downtime and utility costs and increases weld efficiency.

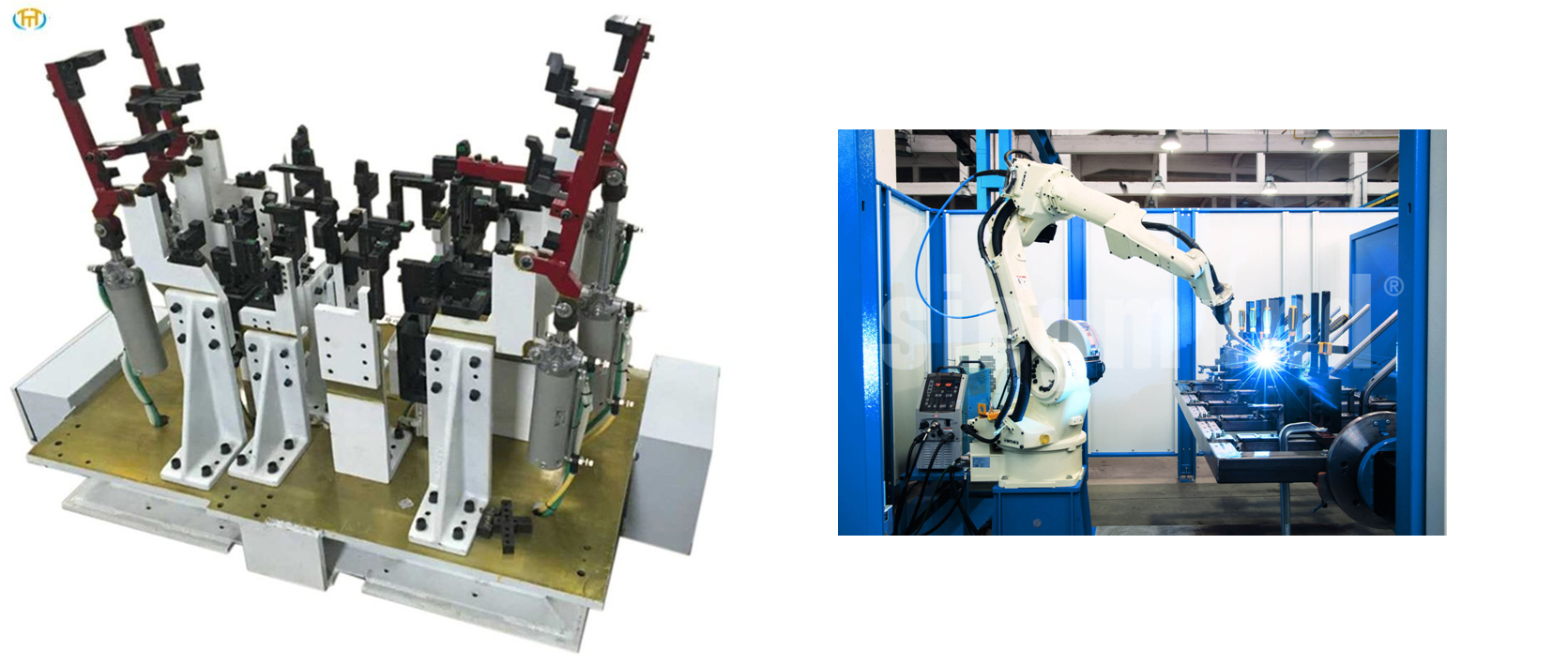

A gripper is a device which enables the holding of an object to be manipulated. The easier way to describe a gripper is to think of the human hand. Just like a hand, a gripper enables holding, tightening, handling and releasing of an object. A gripper is just one component of an automated system. It could be actuated by electric, pneumatic, hydraulic according to the application requirement

We expertise and serve below categoryA Tool Changer is a device which enable the quick change of any end effectors to perform multiple application with same application robotic arm. It could be Manual and Automatic.

We expertise and serve below category

We are specialize in designing and manufacturing jigs and fixture for the industrial automation application our portfolio includes